A design study looking at CC&E's modular design workflow and how this would imapct a sucessfully completed

modular design previously built.

The original approach was successful and met the objectives, however it missed some opportunities.

It didn’t follow the principals established and identified for the best module delivery outcomes.

The design study sets out to assess the implications of adopting good modular design practices; working to the strength’s of the approach.

Key study phases:

- Document the original design objectives, and rephrase or adapt these to a “Modular” approach.

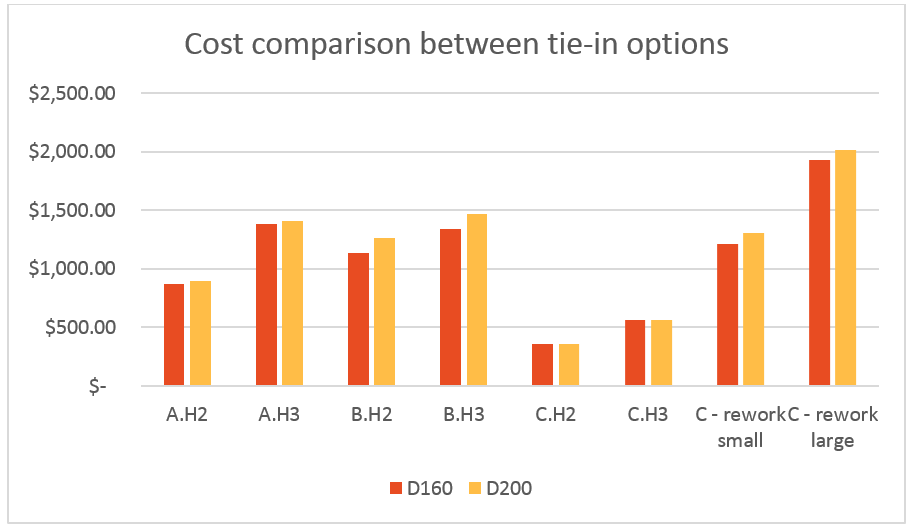

- Prepare a design considering the KIP’s or key metrics which drive installation, fabrication and material supply costs (in that order).

- Review the philosophy for the key module interfaces and integrate with the design.

- Review constructability and finalise the design.

The end result was also a system that's easier to work on and arround.

Contact us for a more details or a discussion on how to benfit further from modualr design and prefabrication.